Engineering Design & Fabrication

Innovation comes standard.

Engineering Design & Fabrication

Innovation comes standard.

We Are Inventing Forward.

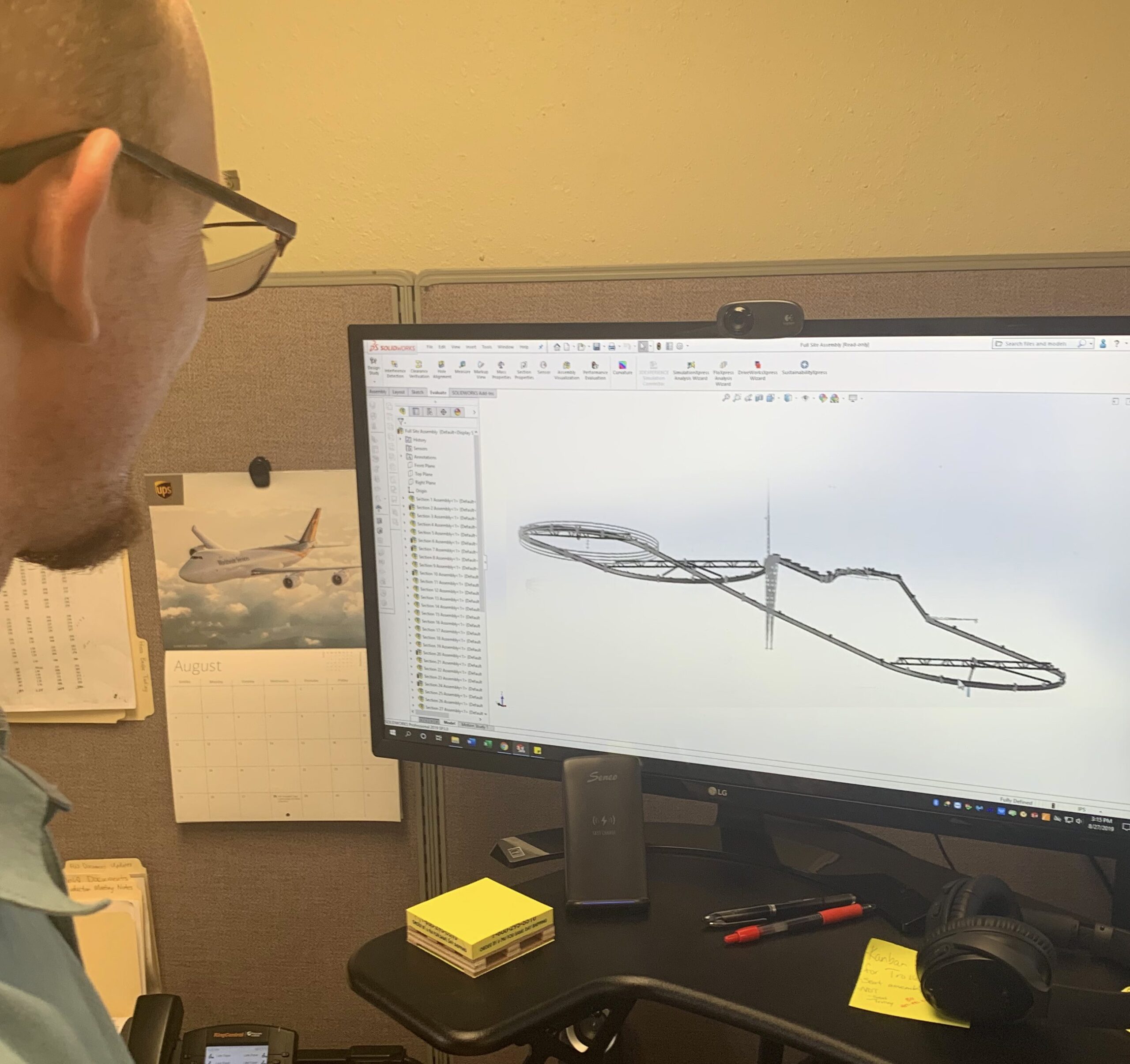

Our team of mechanical and aeronautical engineers holds degrees from prestigious institutions around the world, with a combined experience of over decades in engineering design. We have worked with leading companies such as Universal and Disney. Additionally we have provided services for renowned companies including Ferrari World, NASA, Merlin Entertainments, Six Flags, Dollywood and many others.

Engineered, Tested & Built In America.

Today Extreme Legacy is recognized as the industry leader, supporting amusement ride manufacturers and A&E firms, with creative, turnkey product development solutions and manufacturing support. All of Extreme Legacy’s designs meet industry standards such as CE, ASTM, EN, TUV and can meet CSEI.

Our State Of The Art People.

Extreme Legacy’s headquarters are in Orlando, Florida. Our state-of-the-art production and R&D facility is also located in the U.S.

What We Do

Mechanical Engineering

With expertise in mechanical engineering and design, we can assure you the product will be built correctly, safe and precise the first time. Engineering is in our DNA.

Analysis

We don’t just build something, we test it! The most crucial step in all of our designs is detailed analysis. We make sure analysis is applied to all product designs prior to production. Our expertise in analysis procedures provides the right design for the right job.

Electrical Engineering

We partner with some of the best electrical engineers in the field. Many of our product designs involve electrical hardware development, software development and electrical testing. If your product design requires electrical engineering we can manage this for you.

Prototyping

Quick prototyping allows our customers to ensure the function, design and aesthetics of their product design. We can offer a full scale prototype to a scaled 3D printed or CNC first article. We work with some of the latest technologies available in providing accurate prototypes that help our customers visualize their reality.

Production

Our production facility can accommodate high-volume, precision products and parts at competitive rates. From transport trailers for expensive airplanes, roller coasters, tractor attachments, custom brackets, support columns to funiculars, we can build it all! We can easily ship anywhere in the world. We can deliver the best products in the world in a timely manner.

Bethanys Children’s Health Center

After completing the initial engineering design for Storyland Studios, Bethany Children’s Health Center collaborated further with Extreme Legacy to bring this extraordinary project to life. The caterpillar structure’s vibrant colors will be visible from afar along Route 66 and will feature interactive LED lights, which will dance and illuminate the structure at night.